How to Anti-static for LED Display Interactive LED floor ?

In actual production and application, electrostatic problems occasionally cause damage to the interactive LED floor of the LED display. For example, when an LED is on an electrostatic body and one electrode touches the electrostatic body and the other is just hanging, someone touches the hanging electrode, which may damage the LED.

To minimize the harm of static electricity to the LED display, manufacturers, dealers and customers need to strictly enforce ESD20 during production, transportation and use. 20 standard. In production, the direct and most effective anti-static method is to discharge static electricity to the earth through wire connection.

Electrostatic prevention at production end

_Train personnel using electrostatic sensitive circuits in electrostatic knowledge and related technologies;

During the production process, workers are required to wear grounded electrostatic hand rings. Especially in foot cutting, plug-in, debugging and post-welding operations, and do a good job of monitoring, quality personnel must do hand ring static electricity test at least every two hours, and make good test records;

When welding, the electrostatic low voltage thermostatic iron should be used as far as possible and keep good contact with the ground.

_In the assembly process, use the low voltage DC electric generator (commonly called batch) with grounding wire whenever possible;

Guarantee the effective grounding of production rack, filling rack, aging rack, etc.

Require that the production environment be grounded with copper wires, such as floors, walls, and ceilings used in some occasions, all use antistatic materials. Normally, plaster ceilings and plain wallpapers or plastics wallpapers are prohibited even though plaster and lime-coated walls can be used.

Full color LED display interactive LED floor products should always be stored in anti-static packages or containers during daily operation.

Transport Static Prevention

When transporting, the transport vehicle shall be grounded, and the box or other equipment shall have conductive wheels or tow zippers;

Keep the correct method of handling when you touch the interactive LED floor product, and do not touch the PCB board and the electronic components on it directly.

Client Electrostatic Prevention

When installing the screen, customers and engineers should also strictly follow the anti-static operation and do not directly contact the core electronic components of the product without protection measures.

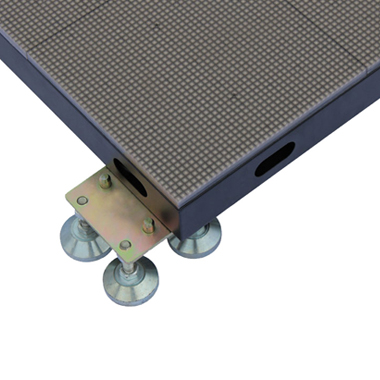

When installing the steel structure of the screen, do a good job of grounding effectively, and bring the static electricity of the screen to the ground.

评论

发表评论